Battery energy storage plays a key role in enabling the future energy system of the United Kingdom.

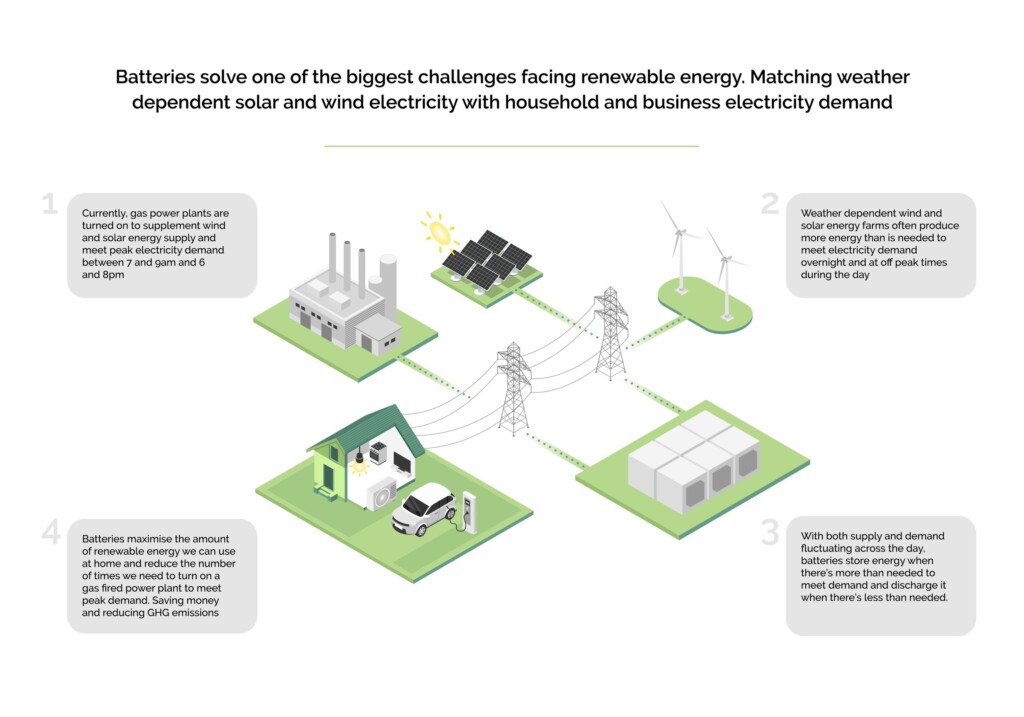

The UK has made significant progress towards a low carbon electricity system, with wind and solar energy now accounting for one third of electricity generation. However, where previously coal-fired power plants were turned up and down to balance the network – matching electricity supply with demand – wind and solar generation is weather dependent. This presents significant challenges for network operators.

Battery storage will provide much of this network balancing role in the UK’s transition to a renewable energy powered electricity network. With wind and solar generation fluctuating across the day, batteries will store energy when there’s more than needed to meet demand and discharge it when there’s less than needed.

Aside from network balancing, battery storage also provides other fundamental ‘healthy network’ features such as grid stability. Where in the event that a major power source, such as a wind farm, goes offline, power from batteries can be deployed instantly to re-balance the network.

Ensuring cleaner, lower-cost energy in the short term

Supporting the long-term transition to zero-emission transport and heating

The next 25 years will see electricity demand double as our petrol cars and gas-fired heating systems are replaced by electric versions to achieve the UK’s target of reducing carbon emissions to zero by 2050.

Battery storage will minimise the costs of this transition by reducing the number of new solar and wind projects required to meet this increased peak demand for electricity and the level of investment in strengthening the UK transmission network to transport energy from offshore wind farms to UK homes.

What is a battery energy storage system and how is it built?

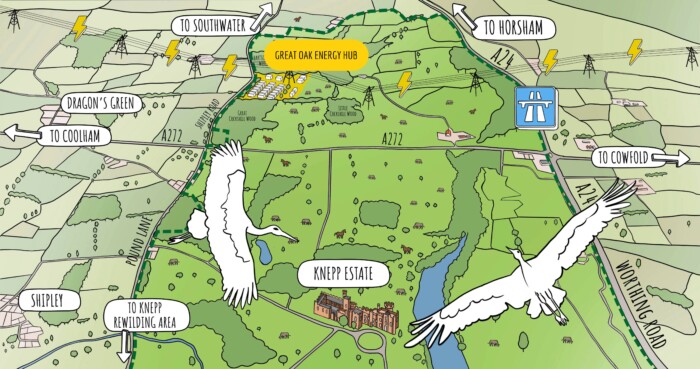

We call our battery storage projects “Energy Hubs” because the energy they store ensures a constant balance between supply and demand. The basic components of an Energy Hub are the well-known lithium batteries, used in devices like cordless vacuum cleaners and electric vehicles. These individual battery cells are connected to form larger units, housed in individual containers.

Each container is capable of powering 2,000 homes for four hours. Each container is connected, via an inverter that converts electricity from direct current (DC) to alternating current (AC), to a substation on-site, which acts as an interface between the project and the electrical distribution network.

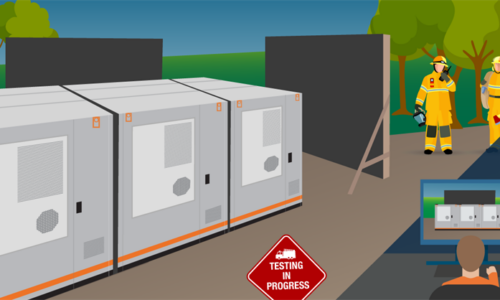

Almost everything is manufactured off-site to reduce construction times and disruptions. The prefabricated containers housing the batteries and inverters are placed on shallow concrete platforms, and everything is connected before final testing.

Designing Energy Hubs to ensure safety and minimize the impact on the neighborhood

Both the battery containers and the entire site are designed to ensure safe operation throughout the project’s lifespan, with individual battery cells continuously monitored and remotely controlled if necessary.

Clearstone has developed a safety strategy for battery storage in collaboration with security experts from AECOM. This strategy ensures that the systems used not only meet the design standards established by safety organizations, such as the National Fire Protection Association, but also undergo hundreds of hours of rigorous testing to verify the proper functioning of safety systems.

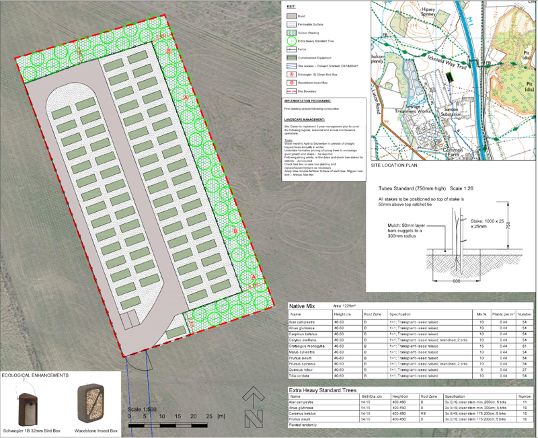

Project sites are carefully selected based on the presence of existing visual screens such as roads, paths, houses, and raised viewpoints. These screens can include trees, hedges, other buildings, or natural features like slopes and ridges. Additionally, additional planting typically creates a green belt at least seven meters wide around the site, making it virtually invisible to local residents and passersby. Acoustic assessments are carried out for all sites, and in densely populated areas, planting may be supplemented with a soundproof fence to contain noise within the site.

We treat each one of our projects as an opportunity to increase biodiversity and strengthen natural ecosystems. To deliver on this commitment up to half of the project site is set aside for dedicated ecological enhancements. While sustainable practices minimise emissions and materials wastage across the project lifespan.

- Use of concrete on site is minimised with access roads and paths constructed from permeable materials to encourage drainage

- Wildflower and grass planting between the battery containers encourages insects and pollinators

- Using native trees and shrubs to construct site boundaries creates new wildlife habitats

- Dedicated wildlife enhancement areas within the project site usually include ponds, bat and bird boxes, butterfly banks and log pile housing

Each of our projects delivers a minimum 20 per cent increase in biodiversity. Where possible, all construction and battery materials are recycled at the end of their operational lifetime or the end of the project.

Anatomy of a battery project

Discover the key components of a battery energy storage project

Converts current from DC to AC

Increases the voltage to meet the level required by the local grid